How Strong Is Super Glue & Baking Soda?

Do you want a way to make your super glue extra super?

This may sound crazy, but add some baking soda.

There is a chemical reaction when you add baking soda to your super glue and it increases the strength over just super glue alone. The bicarbonate molecules in the baking soda react with the cyanoacrylate (the proper name for super glue) and together they create a reactive ion that bonds with the cyanoacrylate.

These bonds create long polymer chains that are stronger than the cyanoacrylate itself.

To prove this, Inventor 101 shows 3 examples of the strength of the bond. He uses a plastic bottle cap, a screw, and the baking soda glue mixture to hold up a 28 pound weight. He also shows how you can use the mixture to fix broken washers, as well as filling a hole that was stripped and no longer fits the nail on the back of a picture frame.

The most impressive of the 3 hacks, the strength test, shows just how secure and strong the mixture is when fully dried.

The video starts by sanding the top of a plastic bottle cap to allow for easier bonding, then adding the super glue and placing a screw on top while it is still liquid. Then, more super glue is added and a small amount of baking soda is poured on to it. Once it hardens, this process is repeated one more time to ensure it is properly bonded.

After waiting the appropriate amount of time for the mixture to fully harden and cure, he puts it to the test.

The bottle cap is secured to a tabletop and out comes the 28 pound weight. The weight has a cord tied onto it which is then hung over the screw and it manages to hold the weight easily. The presenter even gives the weight a little swing to showcase how sturdy it is.

fixes a broken washer.

Some of the grooves of the washer have broken off and need to be replaced, the super glue and baking soda mixture does the trick to get it back to construction worthy standards. The process outlined in the video includes creating a mold using glue gun glue and then fitting the super glue mixture into that. Again, it requires multiple layers of the glue and baking soda and a few hours to properly harden.

The final demonstration tackles an issue that lots of home owners face.

The back of a picture frame, or mirror, that has been constructed with the not-so-great product called OSB (oriented strand board), somehow got damaged. OSB is known to easily chip and break and, like in this example, get stripped by improperly removing a nail. Inventor 101 fills the too-big hole that was leftover with multiple layers of the super glue and baking soda mixture until it is level with the rest of the board. After waiting for it to properly harden, he drills a new hole right into the glue mixture and it problem is now fixed.

Always ensure you are in a well ventilated area while using super glue, and remember to let it harden before moving on to the next step in the process.

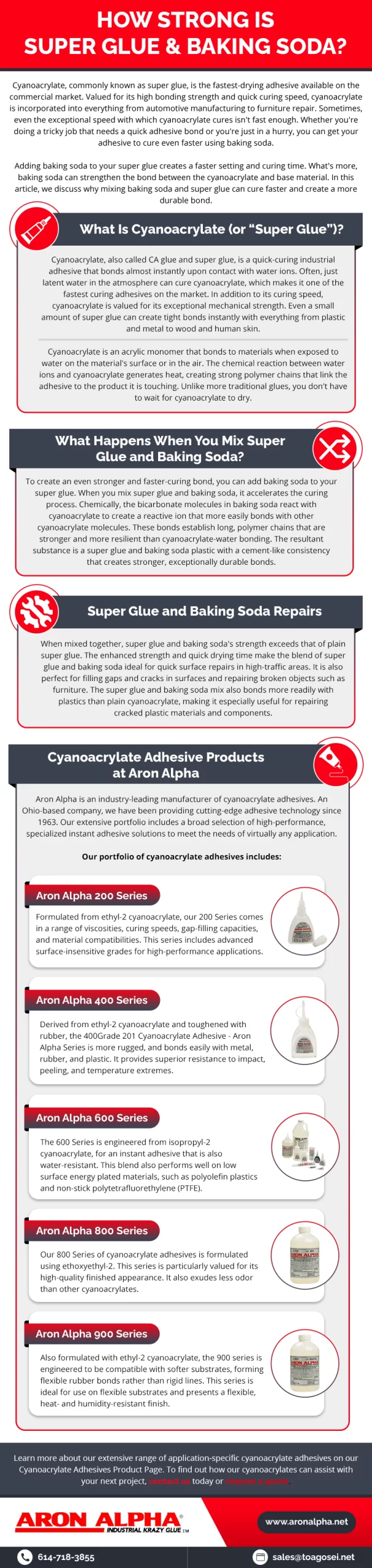

Cyanoacrylate, commonly known as super glue, is the fastest-drying adhesive available on the commercial market. Valued for its high bonding strength and quick curing speed, cyanoacrylate is incorporated into everything from automotive manufacturing to furniture repair. Sometimes, even the exceptional speed with which cyanoacrylate cures isn’t fast enough. Whether you’re doing a tricky job that needs a quick adhesive bond or you’re just in a hurry, you can get your adhesive to cure even faster using baking soda.

Adding baking soda to your super glue creates a faster setting and curing time. What’s more, baking soda can strengthen the bond between the cyanoacrylate and base material. In this article, we discuss why mixing baking soda and super glue can cure faster and create a more durable bond.

What Is Cyanoacrylate (or “Super Glue”)?

Cyanoacrylate, also called CA glue and super glue, is a quick-curing industrial adhesive that bonds almost instantly upon contact with water ions. Often, just latent water in the atmosphere can cure cyanoacrylate, which makes it one of the fastest curing adhesives on the market. In addition to its curing speed, cyanoacrylate is valued for its exceptional mechanical strength. Even a small amount of super glue can create tight bonds instantly with everything from plastic and metal to wood and human skin.

Cyanoacrylate is an acrylic monomer that bonds to materials when exposed to water on the material’s surface or in the air. The chemical reaction between water ions and cyanoacrylate generates heat, creating strong polymer chains that link the adhesive to the product it is touching. Unlike more traditional glues, you don’t have to wait for cyanoacrylate to dry. In fact, in particularly dry conditions, you may have to add water to the surface material to initiate the bonding process.

What Happens When You Mix Super Glue and Baking Soda?

To create an even stronger and faster-curing bond, you can add baking soda to your super glue. When you mix super glue and baking soda, it accelerates the curing process. Chemically, the bicarbonate molecules in baking soda react with cyanoacrylate to create a reactive ion that more easily bonds with other cyanoacrylate molecules. These bonds establish long, polymer chains that are stronger and more resilient than cyanoacrylate-water bonding. The resultant substance is a super glue and baking soda plastic with a cement-like consistency that creates stronger, exceptionally durable bonds.

Super Glue and Baking Soda Repairs

When mixed together, super glue and baking soda’s strength exceeds that of plain super glue. The enhanced strength and quick drying time make the blend of super glue and baking soda ideal for quick surface repairs in high-traffic areas. It is also perfect for filling gaps and cracks in surfaces and repairing broken objects such as furniture. The super glue and baking soda mix also bonds more readily with plastics than plain cyanoacrylate, making it especially useful for repairing cracked plastic materials and components.

Cyanoacrylate Adhesive Products at Aron Alpha

Aron Alpha is an industry-leading manufacturer of cyanoacrylate adhesives. An Ohio-based company, we have been providing cutting-edge adhesive technology since 1963. Our extensive portfolio includes a broad selection of high-performance, specialized instant adhesive solutions to meet the needs of virtually any application.

- Aron Alpha 200 Series: Formulated from ethyl-2 cyanoacrylate, our 200 Series comes in a range of viscosities, curing speeds, gap-filling capacities, and material compatibilities. This series includes advanced surface-insensitive grades for high-performance applications.

- Aron Alpha 400 Series: Derived from ethyl-2 cyanoacrylate and toughened with rubber, the 400 Series is more rugged, and bonds easily with metal, rubber, and plastic. It provides superior resistance to impact, peeling, and temperature extremes.

- Aron Alpha 600 Series: The 600 Series is engineered from isopropyl-2 cyanoacrylate, for an instant adhesive that is also water-resistant. This blend also performs well on low surface energy plated materials, such as polyolefin plastics and non-stick polytetrafluorethylene (PTFE).

- Aron Alpha 800 Series: Our 800 Series of cyanoacrylate adhesives is formulated using ethoxyethyl-2. This series is particularly valued for its high-quality finished appearance. It also exudes less odor than other cyanoacrylates.

- Aron Alpha 900 Series: Also formulated with ethyl-2 cyanoacrylate, the 900 series is engineered to be compatible with softer substrates, forming flexible rubber bonds rather than rigid lines. This series is ideal for use on flexible substrates and presents a flexible, heat- and humidity-resistant finish