14 Types of Wood Joints and How to Choose

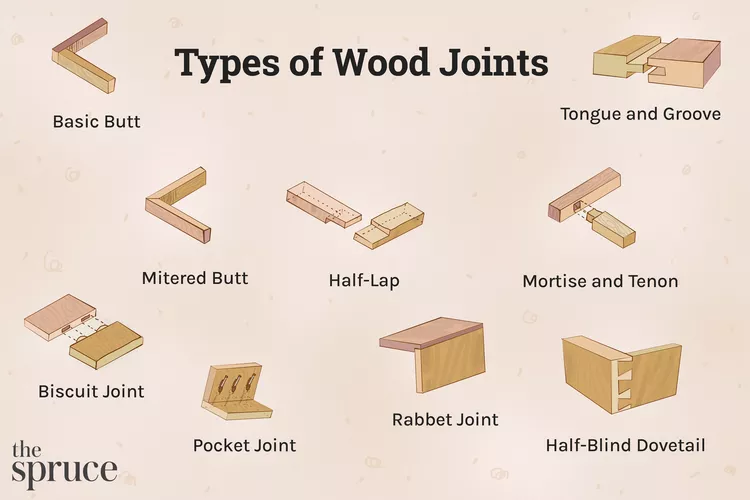

Understanding wood joinery is the key to leveling up your woodworking skills. By getting to know the types of wood joints and when to use them, there’s no end to what you can create out of wood.

While you may already understand the basics, there are several ways to join wood pieces, each serving a different purpose. Some are stronger, some are more aesthetically pleasing, some are complex, and some are simply basic but all that’s needed to get the job done. Read ahead to learn the many common types of wood joints and when to use them.

What Is a Wood Joint?

A wood joint is any direct connection locking together two or more pieces of wood.

How to Choose the Best Wood Joint

Once you understand the different types of wood joints, it’s much easier to deduce which is best for your project. You would never join floor boards together using a complex dovetail joint, just as tongue-and-groove joinery simply doesn’t make sense when building a drawer box.

Once you’ve narrowed down the applicable joint varieties, this decision will come down to striking a balance between complexity, beauty, and strength. Some projects, such as a DIY jewelry box, may prioritize beauty over strength, while more utilitarian projects, such as building a workbench, may call for quick, strong joinery.

Types of Wood Joints

| Strength | Complexity | Common Uses | |

|---|---|---|---|

| Butt Joint | Low | Low | Building framing |

| Mitered Butt Joint | Low | Medium | Trim work, furniture |

| Dowel Joint | Medium | Medium | Picture and mirror frames, chairs, tables |

| Biscuit Joint | High | Medium | Tabletops, cabinetry |

| Dado Joint | Medium | Medium | Shelving, cabinetry, drawer dividers |

| Rabbet Joint | Medium | Medium | Shelving, cabinetry |

| Mortise-and-Tenon Joint | High | High | Building framing, tables, beds |

| Finger Joint | High | High | Boxes, drawers, picture frames |

| Dovetail Joint | High | High | Boxes, drawers, tables |

| Half-Blind Dovetail Joint | High | High | Boxes, drawers |

| Sliding Dovetail | High | Medium | Drawer dividers, cabinetry, shelving |

| Half-Lap Joint | Low | Low | Tables, building framing |

| Bridle Joint | Medium | Medium | Tables, desks, benches |

| Tongue-and-Groove Joint | Medium | Medium | Flooring, tables, wood paneling |

-

01 of 14 Butt Joint

:max_bytes(150000):strip_icc():format(webp)/ButtJoint-56aa2b603df78cf772ace0bb.jpg)

The Spruce / Chris Baylor The most basic wood joint is the butt joint, which is the end of one piece of material butting up to another without any shaping done to the material. Because this technique utilizes minimal surface area for glue, it’s generally considered a weak joint unless supported by additional fasteners such as nails and screws. This simple joint is often used in building framing and other applications that utilize additional fasteners for strength.

-

02 of 14 Mitered Butt Joint

:max_bytes(150000):strip_icc():format(webp)/MiteredButtJoint-56aa2b605f9b58b7d0015338.jpg)

The Spruce / Chris Baylor Similar in strength to a basic butt joint but slightly more complex and visually pleasing is the mitered butt joint. This joint consists of angled boards joined at the ends to form a compound angle, such as two boards cut at 45 degrees joined to form a 90-degree angle.

While this joint is weak like a basic butt joint, the miters hide the end grain of both boards, which is of visual value. Because of its ability to hide the end grain and yield a more attractive appearance, mitered butt joints are often seen in finished work such as joining trim pieces in a corner.

Continue to 3 of 14 below. -

03 of 14 Dowel Joint

:max_bytes(150000):strip_icc():format(webp)/GettyImages-696570430-5a93551430371300375bcf8e.jpg)

AMLBox / Getty Images A dowel joint is an improved butt joint that relies on hidden dowels for strength. This joint is done by drilling opposing holes into the two materials and placing a wooden dowel in the holes, typically with adhesive. The dowel acts as a mechanical fastener by bonding with the glue, while also helping to align the pieces. Dowel joints are popular amongst furniture builders and are used for mirrors and picture frames as well as a variety of furniture pieces.

Continue to 4 of 14 below. -

04 of 14 Biscuit Joint

:max_bytes(150000):strip_icc():format(webp)/295867522_fa00bb848b_b-5a6136554e46ba0037f852c7.jpg)

Flickr Like a dowel joint, a biscuit joint relies on a hidden material within the joint that adds strength and surface area for glue. The hidden material in this case is a thin oval-shaped piece of compressed beechwood called a biscuit. The biscuit is covered in glue and placed into slits that are cut into the opposing pieces of stock. The moisture in the glue causes the biscuit to swell, strengthening the glue’s bond. This joint is popular in furniture making, particularly for joining wood to make tabletops.

Continue to 5 of 14 below. -

05 of 14 Dado Joint

:max_bytes(150000):strip_icc():format(webp)/cutting-a-dado-96312431-a356fe595f7b434aa0519c1faa039495.jpg)

JSABBOTT / Getty Images A dado is a three-sided groove cut into a piece of stock for another piece of stock to fit into, forming a right angle. This simple joint is often utilized for furniture building, such as shelving, cabinetry, and drawer dividers.

Continue to 6 of 14 below. -

06 of 14 Rabbet Joint

:max_bytes(150000):strip_icc():format(webp)/GettyImages-597699422-5a650ee2842b17003747b538.jpg)

seen by hotshot / Getty Images A rabbet is nothing more than a dado cut at the edge of a piece of material. A rabbet joint is similar to a basic butt joint, but the removed material adds additional rigidity and surface area for gluing. Additionally, the piece of stock with the rabbet hides the end grain of the other stock, which makes this joint popular in cabinetry and furniture building.

Continue to 7 of 14 below. -

07 of 14 Mortise-and-Tenon Joint

:max_bytes(150000):strip_icc():format(webp)/mortise-and-tenon-corner-joint-timber-frame-139838959-588a7e365f9b5874ee4d5a43.jpg)

John Burke / Getty Images A mortise is a removed section of material within a piece of stock, while a tenon is a projection cut at the end of a piece of stock. A mortise-and-tenon joint is created when the tenon is fitted within the mortise. This strong connection is often utilized in furniture making for joining bed frames and table legs, but can also be found in traditional barn building and home framing.

Continue to 8 of 14 below. -

08 of 14 Finger Joint

:max_bytes(150000):strip_icc():format(webp)/BoxJointJig10-56aa2bf63df78cf772acef90.jpg)

The Spruce / Chris Baylor A finger joint, sometimes called a box joint, is made by cutting a sequence of equidistant square notches in a piece of stock, then cutting opposing notches in a second piece of stock. The two sets of notches, known as fingers, are then laced together. When supported with glue, finger joints boast superior strength due to the immense amount of surface area at the joint. This simple yet effective joint is perfect for boxes and drawers.

Continue to 9 of 14 below. -

09 of 14 Dovetail Joint

:max_bytes(150000):strip_icc():format(webp)/painted-open-drawer-in-oak-showing-dovetail-joints-464853487-9608f71c16904edc811e8fb8b725568e.jpg)

JuanMuino / Getty Images A dovetail joint is a more complex, self-locking iteration of a finger joint that utilizes tapered notches with corresponding tenons that lace together. The tapered design not only creates a beautiful visual visible on both sides of the joint but flaunts an increased level of strength due to the interlocking qualities. This popular joint is a great option for general furniture building and drawers and boxes that require above-average strength.

Continue to 10 of 14 below. -

10 of 14 Half-Blind Dovetail Joint

:max_bytes(150000):strip_icc():format(webp)/GettyImages-122448504-58f4daa73df78cd3fc44b47b.jpg)

Ingram Publishing/Getty Images A half-blind dovetail joint is an even more complex iteration of the standard dovetail joint, which offers the ability to hide one side of the joint while maintaining the superior strength of the tapered dovetail joint. A common use case for this joint is in drawer construction, where visibility of the joint at the drawer front isn’t desired.

Continue to 11 of 14 below. -

11 of 14 Sliding Dovetail

The Spruce / Chris Baylor Think of a sliding dovetail as a combination between a dovetail and a dado joint. This joint features a three-sided channel much like a dado with a tapered shape like a dovetail. This design offers immensely more strength and locking qualities over a standard dado and can be used similarly.

Continue to 12 of 14 below. -

12 of 14 Half-Lap Joint

:max_bytes(150000):strip_icc():format(webp)/ConnectRack-56aa2b715f9b58b7d00154ea.jpg)

The Spruce / Chris Baylor A half-lap joint features a removed section of material equal to half the depth of one piece of stock and a corresponding section removed from a second piece of stock. The two sections are joined together so that the joined materials are flush with one another.

While the removed material can weaken the individual stock pieces, the rigidity of the joint offers some strength if placed in the middle of the board. However, lap joints placed at the end of a board, known as end laps, are significantly weaker. This joint is often used in building framing and furniture building.

Continue to 13 of 14 below. -

13 of 14 Bridle Joint

:max_bytes(150000):strip_icc():format(webp)/3232709670_52138aea4c_k-6e05125431604929ba623803c201eef8.jpg)

Banalities / flickr / CC BY 2.0 A bridle joint is a strong alternative to a lap joint that’s useful in many of the same applications. Rather than two laps joining together, the bridle joint features a tenon on one piece of stock and an open-ended mortise on the second piece of stock. This way, each side of the tenon acts as a gluing surface, which is much stronger than the single gluing surface on the half-lap joint. Bridle joints are popular in the framing of tables, desks, and benches.

Continue to 14 of 14 below. -

14 of 14 Tongue-and-Groove Joint

:max_bytes(150000):strip_icc():format(webp)/7DryFitJoint-56aa2bff3df78cf772acf089.jpg)

The Spruce / Chris Baylor A popular option in flooring and wood paneling: the tongue-and-groove joinery is one of the most self-explanatory wood joints. On the edge of one board is a tongue, on the other, a corresponding groove. When placed together, the boards lock tightly to one another.

Modifying Wood Joints

Many of the wood joints above feature a handful of modified varieties that can increase their strength, beauty, and complexity. Additionally, these wood joints can be paired with mechanical fasteners in some applications, which can add to their strength and save time during construction.

-

What is the strongest wood joint?

While there are many adequately strong ways to join wood, a properly executed mortise-and-tenon joint is the strongest option.

-

What is the easiest wood joint to create?

The easiest wood joint is the butt joint, as it requires no special shaping of the wood before joining. However, there are many stronger and more attractive options that require minimal prep work.

-

What is the most attractive wood joint?

There are many beautiful ways to join wood, each appealing to a different application. However, the dovetail joint is often regarded as the most attractive joint due to its visibility and complex nature.